Adaptek Systems has extensive expertise in sensor and related solid state module testing. These testing systems range from single station lean cell to a fully automated system, PLC or PC based, with data collection or additional automated processes. Typical systems range in throughput from a few hundred parts per hour up to 1800 parts per hour per cell. Completed individual production systems have exceeded 17 million parts per year, achieving the highest levels of 100% testing reliability.

Optional features such as integrated hardware assembly stations, unloading to packing trays, automated part pass/fail sortation and even low cost laser marking stations all are possible with the modular design of an Adaptek testing system.

In many cases systems include simulation of full operational requirements such as:

- Response Time

- Position Repeatibility

- Air Gap Response

- Make/Break Actuation Point

- High Speed Waveform

- Tone Wheel Response Characteristics

- Load or Force Testing

- Function/Output

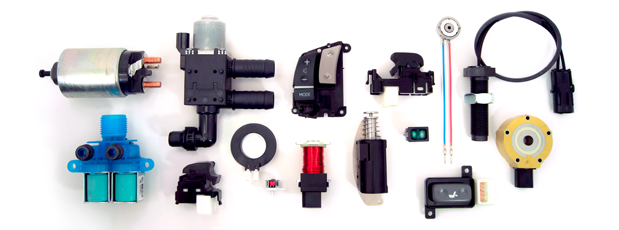

Typical Products Include:

- Variable Reluctance Sensors

- Reed Switch Sensor Testing

- Speed Sensing Sensors

- Proximity Sensors

- Motion Sensor Testing

- Hall Sensors

- Load Sensors

- Sensor Control Modules

- Actuator Modules