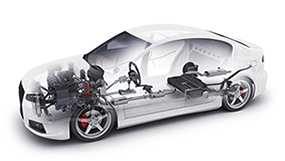

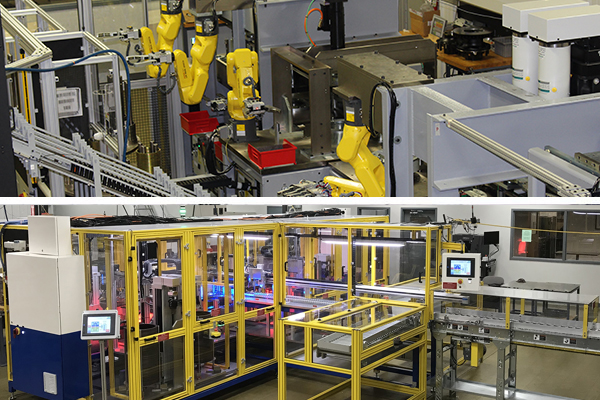

Adaptek Systems delivers high value automation solutions for vehicle drive line component assembly and testing processes. From bearings to suspension, electronics to rotors, the Adaptek Design Team has the experience and is ready for the challenge. Utilizing our patented modular transfer systems, our design team can configure each unique automation solution to match your specific needs. Lean cells to fully automated lines and our expertise of over 33 years of design, build and installation, offers you the options you need to bring the right level of technology to your manufacturing floor.

- Integrated Robotics

- Automated Part Presentation

- High Precision Pressing Stations

- Failsafe Fastener Assembly

- Intelligent Process Control Feedback

- Multi-product Run Capabilities

- Advanced Testing and inspection Options

- Complete data acquisition options